Abrasive Disc Materials for Manufacturing and Automotive Industries

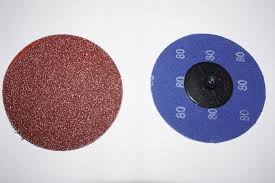

In addition to these characteristics, it’s essential to know what type of abrasive you should work with for the best results. This call will depend on the material of the workpiece, as steel will require a different approach than wood. It also depends on the desired result, whether that’s aggressive stock removal or a smooth surface with no grit scratches. Common options you’ll see when shopping for abrasive discs online include:

- Aluminum oxide: A popular choice of abrasive discs, aluminum oxide is hard, durable and relatively low in cost. It has low heat retention, which makes it great for grinding and sanding many materials. It’s a natural material, but it can also be infused with other chemicals like titanium oxide to create a longer-lasting disc and enhance its abrasion qualities.

- Silicon carbide (SiC): Silicon carbide, unlike aluminum oxide, is synthetic. It’s also friable, meaning it is self-sharpening. It isn’t the most effective when grinding steel or nonferrous alloys, especially with a coarse grit, but it works well on nonferrous, nonmagnetic conductive metals like brass and titanium. Silicon carbide can also abrade wood, stone and glass.

- Zirconium: Zirconium is also friable, revealing a sharp surface edge as it sands. Zirconium is heat-resistant and therefore great for metalwork, especially with steel, iron and titanium. It is better suited to rapid stock removal if used on wood, as it is highly abrasive.

- Non-woven: Non-woven discs are made of nylon fibers held together by synthetic resins. Non-woven abrasive discs are excellent for preparing a metal workpiece for finishing processes. These discs are pliable, making them perfect for grinding and deburring materials ranging from stainless steel to ceramics to glass.

- Ceramic: Another friable abrasive disc, ceramic discs generate much less heat than other types, and they’re great for cutting and grinding harder materials.

Non-Woven Abrasive Discs for Automotive Use

Whether you’re stripping rust and enamel from engine parts or preparing a surface for a final coat of paint, National Abrasives, Inc. has a selection of automotive abrasive discs to choose from. Check out our various sizes of non-woven surface conditioning discs to find one that suits your applications.

Abrasive Discs for Manufacturing

Whether you’re removing stock, deburring edges or preparing a piece of metal for the final finish, National Abrasives, Inc. has a broad selection of abrasive materials to suit your needs, including everything from sanding discs to angle grinder cutoff wheels.

Buy Abrasive Discs Online From National Abrasives, Inc.

National Abrasives, Inc. is a family-owned and -operated company located just south of Harrisburg, Pennsylvania. We’ve served the industrial abrasive materials needs of clients in our local community and across the United States for more than 20 years. We dedicate ourselves to maintaining our reputation for quality products and exceptional customer service with every sale.

We like to think of our relationship with you as more of a partnership, enhanced by our ability to earn the trust of our customers when we provide for their unique needs. If we don’t have what you need, we’ll do whatever we can to find it.

We know how dynamic and fast-paced your industry can be, so we provide same-day shipping on in-stock orders whenever we can. We also help you save money with our competitive pricing and bulk order options.

Browse our current selection of abrasive discs and buy online today! We offer free shipping. If you’d like more information, feel free to contact our friendly team.